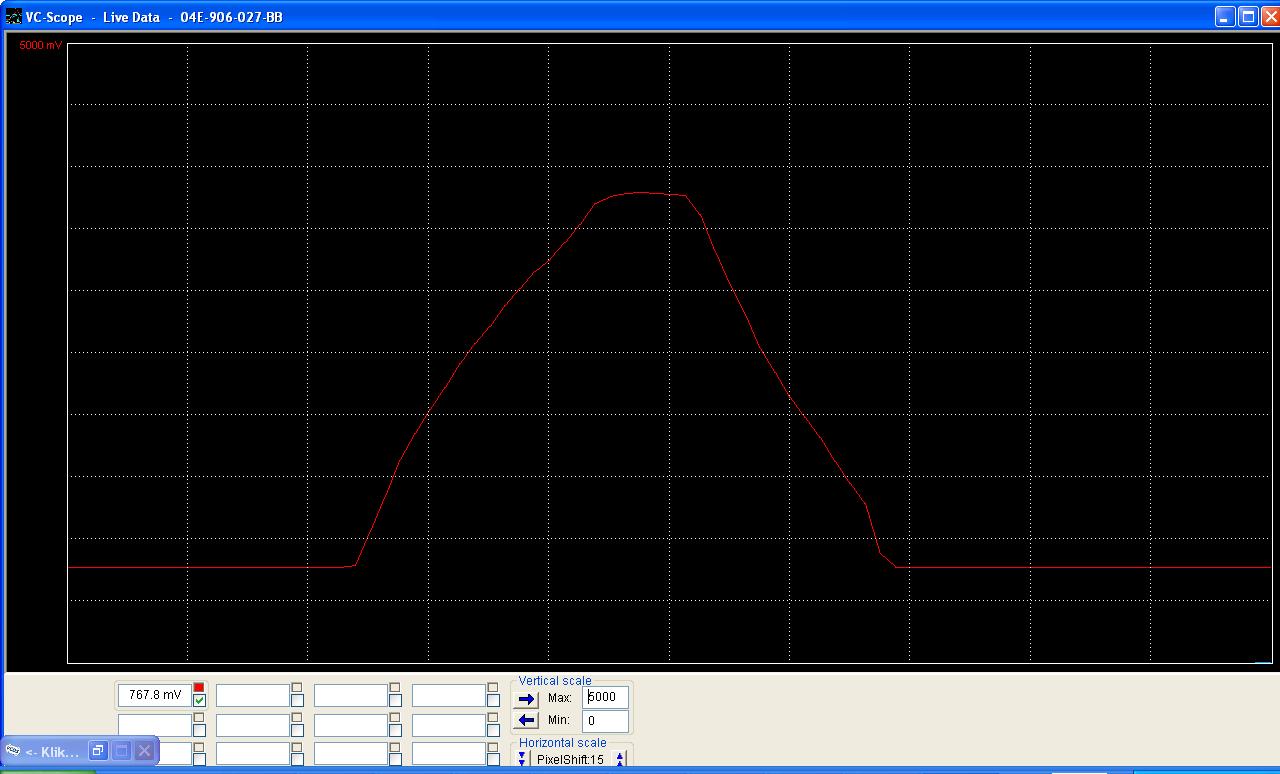

Engines / UDS Engines by part number / 01 - Engine [EV_ECM30BTD0118K5907589 001006] / Test of gas pedal position sensor 1 - voltage (G79)

Mark

Model

Control unit

Diagnostic operation

Mark

Škoda

VW

Audi

Seat

Porsche

Bentley

MAN

Service intervals

Engines

Gearboxes

Immobilizers

auxiliary heater

Model

UDS Engines by part number

Diesel

Petrol

Part 1 of the order number

03C

03E

03F

03H

03L

03N

03P

04B

04C

04E

04L

05C

05E

05L

06J

06K

07C

07P

0EA

1K8

2G0

2H6

36A

3G0

3W0

4G0

4G1

4G2

4G5

4H0

4K0

4KE

4L0

4L1

4L2

4M0

4M8

4ML

4N0

4S0

5FA

5G0

5H0

5N0

5NA

5WA

760

7P0

7P1

7P5

80A

81A

83A

8K0

8K1

8K2

8K5

8R0

8S0

8T0

8T1

8T2

8U0

8V0

8W0

8Y0

W03

W04

W4G

Part 2 of the order number

8K5

8K5907

8K5997

Part 3 of the order number

8K5907115

8K5907311

8K5907401

8K5907551

8K5907589

Part 4 of the order number

8K5907589

8K5907589C

Control unit

01 - Engine [EV_ECM30BTD0118K5907589 001005]

01 - Engine [EV_ECM30BTD0118K5907589 001006]

01 - Engine [EV_ECM30BTD0118K5907589 001007]

01 - Engine [EV_ECM30BTD0118K5907589 001011]

Diagnostic operation

Start/stop - activation/deactivation

Customer limitation of maximum speed

Injector: corrective value - Test

Zeroing learning values DPF - If replaced: DPF

Zeroing learning values DPF - If replaced: pressure difference sensor (G505)

Zeroing learning values DPF - If replaced: engine control unit/DPF

Zeroing learning values - Lambda sensor(s)

Zeroing learning values - Adaptation of the mean quantity value

Deletion of statistics memory - Start-stop

Automatic test procedure

Creation of readiness

Basic settings - turbo blower

Bleeding of fuel system

Test / activation of fuel pump and control relay

Evacuation of fuel tank

Activation - fuel pump (G6)

Test - exhaust recirculation - servo motor (V338)

Test - Change-over valve for the cooler of the exhaust gas recirculation

Test - exhaust gas return valve 1 (GX5)

Test of filling and atmospheric pressure sensor (G31)

Test of intake air temperature sensor (G42)

Test of engine temperature sensor (G62)

Test - Intake air mass sensor - test drive

Test of fuel temperature sensor (G81)

Test of engine temperature sensor - outlet from radiator (G83)

Test of exhaust gases temperature sensor 1;3;4 (G235; G495;G648)

Test of DPF differential pressure sensor 1 (G505)

Test - Neutral gear sensor (G701)

Test of heating (glow) unit (J179)

Test of radiator fan control unit (J293)

Test - voltage: terminal 30 (J317)

Test - throttle valve: control unit (J338)

Test - low heat performance relay (J359)

Test - high heat performance relay (J360)

Test - fuel pump: control unit (J538)

Test - injector 1-4 (N30;N31;N32;N33)

Test - filling pressure control valve (N75)

Test - fuel pressure regulation vlave (N276)

Test - Fuel metering valve (N290)

Kick-down - adaptation

Test - fuel pressure regulation vlave (N276)

Test - engine control unit (J623) - power supply

Test / activation of fuel pump and control relay

Test of filling pressure

Test of load signals for alternator

Test of gas pedal position sensor 1; 2 (G79; G185)

Bleeding of fuel system

Evacuation of fuel tank

Creation of readiness

Customer limitation of maximum speed

Deletion of statistics memory Start-stop

Bleeding of fuel system

Bleeding of fuel system variant II

Evacuation of fuel tank

Evacuation of fuel tank II

Creation of readiness

Automatic test procedure

Test - fuel pressure - pressure sensor (G247)

Test of load signals for alternator

Test of gas pedal position sensor 1 - voltage (G79)

Test of gas pedal position sensor 1; 2 (G79; G185)

Test of gas pedal position sensor 2 - voltage (G185)

Test of engine temperature sensor - outlet from radiator (G83)

Test of intake air temperature sensor (G299)

Test of fuel temperature sensor (G81)

Test: temperature sensor - ambient temperature (G17)

Bleeding of fuel system variant III

Evacuation of fuel tank III

Kick-down - adaptation

Test of filling and atmospheric pressure sensor

Bleeding of fuel system - variant 2

Adaptation of injection valve after replacement

Turbo blower - replacement (adaptation)

Zeroing learning values - Quantity measuring unit - regulator valve

Creation of readiness

Adaptation of injection valve after replacement CLHx;CNHx

Adaptation: oil presure for engine run-in

Test - Intake air mass sensor - test drive

Test - idle stabilization

Injector: corrective value - Test V5

Injector: corrective value - Test V6

Security access: blocking detection

Diagnostic procedure

You are not logged! System works in DEMO mode only now where numbers are replaced with X characters. For 49 EUR onl y You will get access into full system. You can pay by credit card or bank transfer. Click BUY button for purchase and You will get login to diagnostic procedures database imediatelly.

Log-in

Buy

Conditions: •

engine speed = X rpm connect with the control unit XX - engine Advanced Measured Values select item in menu : IDEXXXXX - accelerator pedal: voltage X-V_PVS_X_BAS (GXX) TIP! For easier search in the menu, enter the code IDE, ENG or MAS into the "Filter" window Start alternately operate the accelerator pedal Move the line and connector connection on the sensor and observe whether the values do not change sharply accelerator pedal: released = X.XXV - X.XXV accelerator pedal: depressed = X.XV - X.XV X.XV - X.XXV Picture documentation: if values are not achieved, check part: - accelerator pedal: Position sensor (GXX) end

You are not logged! System works in DEMO mode only now where numbers are replaced with X characters. For 49 EUR onl y You will get access into full system. You can pay by credit card or bank transfer. Click BUY button for purchase and You will get login to diagnostic procedures database imediatelly.

Log-in

Buy

Diagnostic procedures for a VAG diagnostics

Diagnostic procedures for a VAG diagnostics Database for coding vehicle control units Volkswagen - VAG

Database for coding vehicle control units Volkswagen - VAG Software versions

Software versions VIN - Code validator

VIN - Code validator